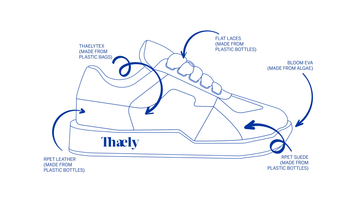

See how your Thaelys are made

We made a fabric that looks and feels like leather but is made entirely out of waste plastic bags, without the use of any chemicals

Thaely Tex

Used for the Upper

ThaelyTex® is a revolutionary new fabric that looks and feels like leather but is made entirely out of waste plastic bags, the production process does not need any additional chemicals nor does it release any toxic chemicals as a by-product. The production process is designed to be safe, cost effective and to have the lowest emissions possible.

Each sneaker uses ThaelyTex that’s made using 10 upcycled waste plastic bags. ThaelyTex is made in collaboration with VIRENDERA TEXTILES in Haryana and AIRDROPS in New Delhi, India. The waste plastic bags are collected from housing complexes, offices and stores from in and around Delhi. The collected plastic bags are then segregated, sanitised and processed into ThaelyTex. All waste management professional are paid fair wages, have access to safe working conditions.

rPET

Used for the Toe Box, Lining, Laces and Tote

rPET or Recycled Polyethylene Terephthalate is a fabric made from recycling waste PET Plastic Bottles. rPET is the same as virgin polyester in terms of quality, but its production requires 59 percent less energy compared to virgin polyester. All our rPET is sourced from VIRENDRA TEXTILE, HARPER and Waste2Wear India.

Unlike most other fashion brands, the rPET we use is 100% certified recycled and not 1blended with any other virgin materials. Each sneaker uses rPET that’s made using 12 Recycled waste plastic bottles.

Recycled Rubber

Used for the Sole and Insole

Recycled rubber is rubber that has been reclaimed from scrap materials such as used shoe soles, tires and other industrial waste. Recycling rubber means that millions of scrap shoe soles and tires are no longer dumped in landfills, or left illegally in lakes, abandoned lots, along the side of the road and in sensitive habitats. In fact, recycling rubber saves impressive amounts of energy, which ultimately reduces greenhouse gas emissions. For example, recycling four tires reduces CO2 by about 323 pounds, which is equivalent to 18 gallons of gasoline. Using recycled rubber in moulded products like our sole, for example, creates a substantially smaller (by a factor of up to 20 times) carbon footprint as compared to using virgin plastic resins.

Our recycled rubber soles are sourced from Enky Rubber group, India. Our soles use about 40% Recycled rubber in their construction. Our insoles use a blend of recycled rubber and waste from castor bean oil production.

Printable Recycled Paper

Used for the Box

The Thaely Y2K Pro box is made from recycled paper which is embedded with basil seeds and dyed with waste coffee grounds. Once you get your box simply cut and plant it. You will have a basil plant in 10 days - ready for pesto. Our box is sourced from Plantables in Agra, India.

Bloom Materials

Bloom EVA

(Made from Algae)

Used for Reflex Runner’s Sole

Bloom is your environmentally-conscious, high-performance replacement for traditional petroleum-based EVAs. Foams utilizing Bloom’s algae technology deliver striking performance values, which make them excellent replacements for conventional foams. Algae’s natural thermoplastic qualities allow Bloom to meet, and in some cases exceed performance characteristics of conventional closed-cell flexible foams. Bloom is an algae-blended resin containing a significant fraction of algae biomass and bio-based additives. Bloom has a renewable content of at least 45%, offsetting a significant portion of traditional EVA required for footwear foams